Phison S10: Toshiba MLC And TLC Versus Micron L95B MLC

- Introduction

- Technical Specifications

- A Closer Look

- Sequential Read

- Sequential Write

- Random Read

- Random Write

- Mixed Workloads

- 128KB Sequential Mixed-Workload Steady State Performance

- 4KB Random Write Steady State Performance

- PCMark 8 Real-World Software Performance

- Total Storage Bandwidth

- PCMark 8 Advanced Workload Performance

- Latency Tests

- Notebook Battery Life

- Conclusion

Phison offered to let us test its S10 controller with three flash types that will ship in 2015: Toshiba's A19 TLC, 15nm MLC and Micron L95B 16nm MLC.

Three components are needed for every SSD. The controller is perhaps the most talked-about piece. After all, the second element, firmware, sits on the controller side, often changing the way the processor behaves over a drive’s life. The third element is flash memory, the puzzle piece responsible for holding your data. Sometimes a model will launch with one type of flash, only to be updated with new NAND as the older technology becomes obsolete.

Today we’re testing three flash types on the same controller and same generation of programming. For the most part, flash is the variable. The two other significant components that affect performance are held equal. Kinda makes for a dreary-sounding article, right? To the contrary, aside from Samsung’s drives, any of the SSDs you consider for the rest of 2015 and early 2016 will use the flash we’re covering. And just to be certain we hit all of the important angles, we’re testing across three popular capacities: 256GB, 512GB and 1TB.

You may wonder just how much difference flash makes in an SSD. That’s what we’re going to demonstrate. Factors like write endurance need to be considered, and we usually talk about that in product reviews since the variables tend to change over time (think increased yields and refinements to the manufacturing process). Price also plays a role. At this year’s Computex, we were told that Toshiba A19 MLC currently costs around 30% more than Micron’s L95B (16nm MLC). When Micron shifts production over to 3D at the end of 2015, that could change. When Micron moved to 20nm from 25nm, a shortage increased NAND spot prices and retail drive prices increased for a few months. Flash is the most expensive component in client SSDs, so it’s important for us to keep a watchful eye on trends and new technology as it moves into products you may want to purchase.

Technical Specifications

Phison’s S10 controller consists of a quad-core CPU, 32 flash CEs (expanded to 64 CEs), DDR3 support, a 256-bit AES on-the-fly engine and end-to-end data path protection.

Before we dive into the flash, let’s take a closer look at the S10 and why we chose to use it for this project. Phison is an agnostic controller manufacturer. The company doesn’t produce NAND, so it doesn’t favor one type of memory over another. In order to thrive, Phison has to support every type of flash.

Phison doesn’t sell retail products. Instead, it enables the companies you’ve purchased SSDs from to create new offerings. The S10 controller we’re using today is already shipping inside of Corsair’s Neutron XT, the HyperX Savage, Patriot’s Inferno and Mushkin’s Striker. Some of those drives use Toshiba A19 MLC flash and others use Micron L95B 16nm MLC.

Phison is working on firmware that will enable more advanced features, allowing the S10 to work in more markets. At Computex, we saw designs like the enterprise 2TB model with full host power fail protection. The S10 is a Swiss Army controller that can take on any role through quality engineering. Moving forward, the S10 should address the following markets:

Enterprise

Hyperscale computing requires consistent performance and low latencies. The choice of NAND is what defines whether an SSD can handle read-intensive or write-intensive workloads. You’ll see those characteristics in the drive-write-per-day (DWPD) specifications.

In addition, the PLM features on S10-based drives provide protection against sudden power loss, which is key to the zero-downtime requirement of many enterprises. This is especially useful if a storage system does not enjoy the benefit of SSDs in RAID.

Industrial

Industrial SSDs are often utilized in environments with hostile temperatures, vibration and humidity. The S10 controller supports industrial-grade options from -40 to 85 degrees C. The PLM features also come in handy for industrial applications, since some of those demand zero downtime as well.

High-end Client

The quad-core S10 controller enables performance that can almost saturate the SATA interface. It’s a top performer in several of our performance benchmarks. Gaming enthusiasts should be excited by its high I/O per second and 560 MB/s throughput.

Entry-level Client

The S10 has a strong ECC engine to enable TLC-equipped SSDs for the entry-level client market, where price is the king. The major challenge of TLC is its endurance and performance. Data protection features help extend the SSD’s useful life. And we expect the performance of S10-equipped SSDs with TLC flash to compete with existing SSDs armed with MLC NAND, making the transition from MLC to TLC largely transparent.

Now, let’s look at the advanced features built into the S10.

Quad-core CPU: the S10 is equipped with quad-core CPU, three of which are dedicated to flash management, sustaining performance when the SSD is in a dirty state. The smaller the swing, the lower the command latency.

256-bit AES Engine: the S10 offers AES-256 encryption options for corporate demands (like TCG Opal) and government regulation (like FIPS-140-2). TCG Opal 2.0 Self-Encryption Drive Technology is also supported, protecting sensitive data from loss, re-purposing or end-of-life.

Eight-Channel and 2TB Support: the S10 operates with eight flash channels and four-way interleaving. It is designed to have enough drive power to support up to 2TB of capacity without sacrificing performance. It also has optional support for full device capacity without over-provisioning.

TLC Support: the S10 is Phison’s first SSD controller supporting TLC. Its BCH ECC engine is specially designed for 1y/1znm TLC flash.

Power-Fail Circuit: the S10 reference design enables full power-loss protection. An on-board capacitor provides the power needed for the controller to flush data from the DRAM to NAND, where it’s secured.

End to End Data Path Protection: this enterprise feature detects and corrects bit errors within the controller data paths.

SmartECC: the ECC scheme implements multiple levels of correction to not only provide the basic ECC engine capability that flash requires, but also extends NAND durability with the addition of page RAID ECC Parity. The Multi-Level ECC scheme can be summarized as follows:

• Level 1: Read Retry

• Level 2: Standard BCH ECC Parity in spare area

• Level 3: Page RAID ECC Parity

Page RAID ECC Parity is able to recover otherwise uncorrectable ECCs with following steps:

1. Uncorrectable error is detected

2. SmartECC engine starts to reconstruct the defective data by using RescueParity that was previously generated and stored in other pages.

3. The recovered data will be stored in a new page. The original block will be marked bad.

SmartRefresh: this feature is to designed fight read disturb. There are two triggering schemes: run-time media scan (RS) and idle-time media scan (IS).

SmartFlush: this is a proprietary algorithm to minimize DRAM utilization for user data. There are two main features:

Smart On-the-fly Flushing (SOF)

• Constant flushing to minimize the time data stays in the cache.

• Re-organize random data chucks in cache before flushing to NAND to reduce WAF.

Smart Triggered Flushing (STF)

• Link Loss Triggering

• DevSlp Triggering

• Idle-Time Triggering

GuaranteedFlush: the Flush Cache command is a standard SATA command to ensure specific data is saved to NAND instead of the DRAM cache, which can help protect important user data against power loss. However, due to the pair-page effect of flash, data written before the Flush command may be affected by data written afterwards.

P-Fail (Full Power Loss Protection) Circuit: for mission critical applications, where full data integrity is desired, the S10 provides the capability to use its on-board capacitor to fully protect un-recoverable data in the DRAM during a power loss event. When voltage drops below a threshold, the power detection circuit kicks in, and the firmware prepares for exit strategies for a safe shut down.

A Closer Look

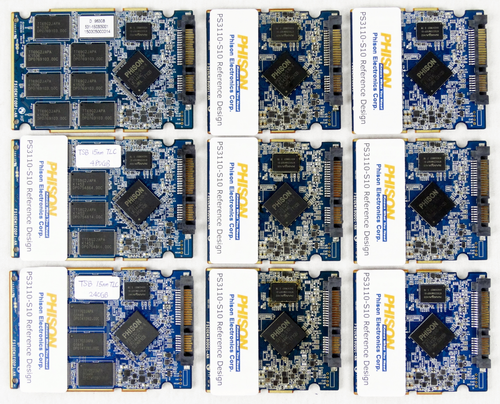

|

|

All nine of the drives we’re testing use Phison’s PS3110-S10 controller and Nanya DRAM. The DRAM buffer is the same size at each capacity point, but grows as you step up through the drives equipped with more NAND. After all, larger SSDs require more DRAM to cache the page table map.

The most interesting flash we’re testing is Toshiba’s A19 TLC. OCZ recently released its Trion 100 family with this stuff, but that’s the only retail product so far with it. All of the A19 TLC flash we’ve seen so far has been in TSOP packages (the silver connection points on the side of the package).

The three A19 TLC drives use 16 NAND flash packages to increase parallelism. The six MLC drives use just eight packages.

The Toshiba 15nm MLC is in BGA packages, with eight on each PCB. Toshiba 15nm MLC is still very rare. At this time, no retail products use this flash, though we expect it to ship in a number of SSDs before the end of the year. This is the most advanced 2D NAND flash process available, allowing Flash Forward (Toshiba and SanDisk’s joint venture) to pack more dies per wafer than any other.

Micron’s L95B (16nm MLC) is in a number of products. Crucial’s MX100 was one of the first SSDs to use it.

At Computex 2015, Micron announced 16nm TLC flash, but we don’t think it will appear in retail products until early 2016. Micron’s 16nm TLC retains the same 128Gb density per die, though the die is 28% smaller than L95B.

Sequential Read

To read about our storage tests in-depth, please check out How We Test HDDs And SSDs. Four-corner testing is covered on page six.

The charts are a little different today. Instead of ordering the results from highest to lowest performance, we grouped them by capacity. We have three capacities and three different types of flash.

The Toshiba A19 TLC 480GB drive gave us an odd result. But aside from that one score, the rest of the drives finish where we expect them to.

S10-controlled retail products like the Corsair Neutron XT, Kingston HyperX Savage and Patriot Inferno all deliver exceptional sequential read performance. The three examples lead our charts in this test with more than 560 MB/s, the upper limit of SATA 6Gb/s.

Sequential Write

We really want to pay close attention to write performance. These days, enthusiasts pay more for this specification since read performance is almost always at the limit of SATA 6Gb/s anyway.

The two smaller drives with Toshiba A19 TLC get close enough to steady state during this portion of the test script that their numbers waver. We also see that a capacity advantage doesn’t always translate to significantly higher write performance when it comes to TLC flash. The 960GB TLC drive delivers less sequential write performance than the smaller 480GB MLC versions. The same performance drop-off also occurs in the 480GB TLC drive compared to 240GB MLC drives.

Random Read

Our random read tests, just like the sequential read tests, show similar performance across all drives. In short, Toshiba MLC flash delivers higher random read performance than Micron’s 16nm MLC. This is a lesson that goes all the way back to the 3xnm lithography days. The difference is small on the desktop, however, enterprise SSD users are more sensitive to it. OCZ even took advantage of Toshiba’s higher random performance when it released a series of products with Max IOPS branding.

Random Write

Toshiba A19 TLC takes a large performance hit in the random write category. At QD32, TLC delivers around one-third the random write performance of MLC flash from Toshiba and Micron. The MLC advantage is even greater at 256GB. We expected the 16-package TLC to perform a better than it did, if only because of the increased parallelism. It will be interesting to see what happens when a company uses just eight packages with TLC; performance may drop down to 10,000 random write IOPS.

At a queue depth of one and two, the TLC drives close the gap. TLC-based products will make up the entry-level SSD market, so they’ll be used for Web surfing, light gaming and general productivity tasks. Their performance is ample for those activities, and still well beyond what you’d get from a disk drive.

Mixed Workloads

Our mixed workload testing is described in detail here, and our steady state tests are described here.

In some tests, the 240GB TLC drive performs a little better than some of its competition. I’m not sure if the lower capacity paired with TLC triggered more aggressive garbage collection, which just happened to show itself in the 80% read portion of our script or if some other factor contributed. Companies will get very creative with TLC to increase performance.

The mixed workload random test shows all three TLC drives exhibiting higher performance than the MLC drives. All of the benchmarks discussed so far use 100% entropy (incompressible data). Phison’s controller performs better with compressible data, as we’ve demonstrated.

128KB Sequential Mixed-Workload Steady State Performance

Measuring sequential steady state performance, we get back to the results we expected, with Toshiba 15nm MLC outperforming Micron MLC as the TLC flash trails.

On the line chart, we also get to see 100% sequential steady state write performance. All three of the TLC drives deliver around 100 MB/s regardless of capacity. This is true TLC sequential write performance without emulated SLC buffers increasing burst performance.

4KB Random Write Steady State Performance

The first image that shows the preconditioning phase is all but useless with this many drives, particularly when they all have such a large spread between high and low performance.

The second image offers a clearer look at what the drives do once they’re in steady state. We see there is more of a relationship between capacity and low steady state performance than there is the type of flash used. The TLC burst increases are spread further out than the spikes with MLC.

PCMark 8 Real-World Software Performance

For details on our real-world software performance testing, please click here.

For most users normally running single applications, who don’t pound the drive with heavy writes, TLC’s performance limitations won’t be a deal breaker. Flash, be it SLC, MLC or TLC, isn’t stressed by normal client workloads.

Total Storage Bandwidth

Overall performance over time shows that MLC flash is faster, but normal user latency between commands absorbs the performance differences. It really comes down to the workload. And for most users, TLC delivers a large enough performance increase over hard disk drives to make it attractive on the desktop.

PCMark 8 Advanced Workload Performance

To learn how we test advanced workload performance, please click here.

Under heavier workloads, MLC is still a better option though. It really comes down to the workload you’re running. In a more demanding test, the emulated SLC buffer can’t flush fast enough to the flash that writes steady state sequential data at roughly 100 MB/s.

Latency Tests

The latency charts show how heavy workloads can affect performance negatively. When it comes to latency, we’re really talking about the user experience. The best SSDs deliver an instant response when you need it. Applications open as you release the mouse button from a double-click. On the other end of the spectrum, disk drives introduce a pause between your request and the time you see action.

Under heavy workloads, TLC yields performance in the middle of those two extremes. Under lighter workloads, TLC-based SSDs perform more like MLC-equipped drives thanks to the pSLC buffer that keeps performance high until the buffer is full.

Notebook Battery Life

In our notebook test, the SSDs with TLC flash deliver more battery life than either of the two MLC-based models. The retail drives we’ve tested that use Phison’s S10 all delivered admirable run time. But it looks like TLC will improve this discipline even more.

With the Lenovo T440 running on battery power, all of the drive exhibit similar performance. This is good news for travelers who routinely spend a lot of time away from wall outlets. Since TLC-based drives reduce the cost of SSDs, many of them will end up in business notebooks deployed in Fortune 500 companies.

Conclusion

We’ve learned a few things about what to expect from next-generation flash. We didn’t include any Toshiba A19 MLC numbers, even though we have the drives here and the tests completed. Toshiba A19 and 15nm perform almost identically, so to keep the charts readable, we didn’t include the A19. Right now, Toshiba’s A19 MLC costs more than IMFT’s 16nm MLC. But on the 15nm node, the tables turn. If both companies keep production numbers up, we’ll see a price war that is very good for buyers.

This really couldn’t come at a worse time for Micron though. I’m writing this story just one day after Micron’s stock dropped nearly 20% after missing sales expectations. It was the first revenue decline in more than two years. Micron blames struggling PC sales, though we think there is more to the story since the company skipped a DRAM lithography generation. Micron is the largest memory manufacturer in the U.S., so it’ll pull through with between $3.4 and $3.7 billion in fiscal Q4 revenue.

Micron’s 16nm MLC is still a great option for performance SSDs, and through 2016 we’ll see a lot of it in client drives. Micron recently developed L95B FortisFlash that allows its partners to program pSLC code that increases endurance and performance.

By the time this article goes live, OCZ will have the Trion 100 with Toshiba A19 TLC for sale online. The pre-launch pricing given to media is decent, though other MLC-based SSDs sell for less.

A19 TLC isn’t as bad as some make it out to be. The endurance of the flash is better than we expected, and controllers with advanced BCH and LDPC will give drives decent Total Bytes Written (TBW) specifications. TLC isn’t for everyone, but it’s good enough for most of us if we’re honest about the workloads we subject our SSDs to. TLC will help chip away at the price of SSDs, so the install base of triple-level-cell memory will increase significantly over time.

Phison helped us make this article possible, so we want to talk a bit about S10 development. The controller obviously works with all of the flash we used today, but it is also ready for 15nm TLC. We’re still waiting on the random write performance increase firmware, and expect this soon. When it hits, the S10 should be strong enough to compete with Samsung’s 850 Pro and SanDisk’s Extreme Pro SATA SSDs. Recent price drops on the Kingston HyperX Savage makes the drive more attractive than when we reviewed it.

[Source : http://www.tomshardware.com/reviews/toshiba-tlc-mlc-micron-mlc-phison-s10,4190.html]